| 2xAWG24+2x2xAWG28 | 2xAWG19 | |

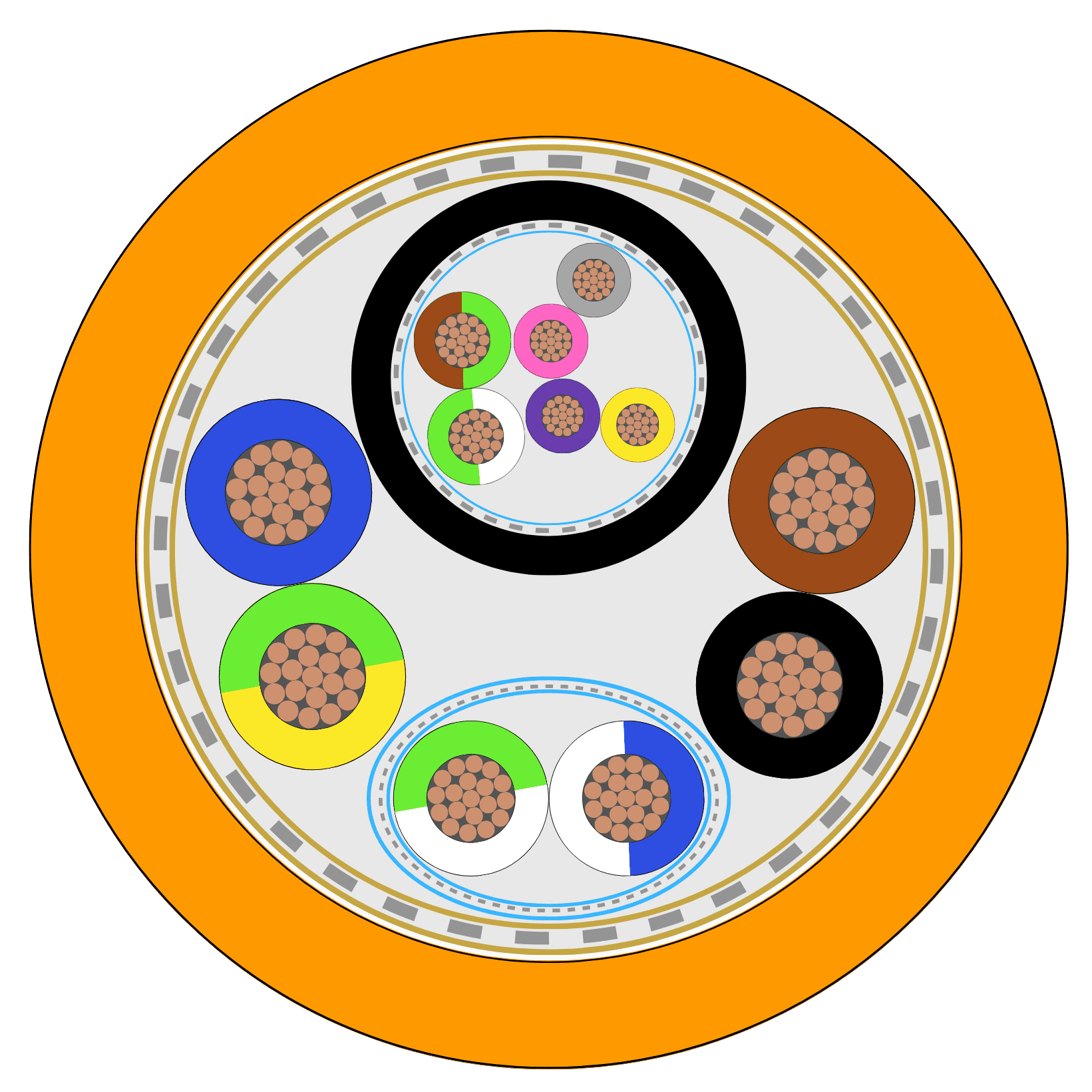

| Conductor AWG28: stranded tin copper wire 0,08mm; nominal 0,10mm² – AWG28; nominal diameter 0,40mm. Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 ⇂ Insulation: polyolefin; nominal diameter 0,95mm ⇂ Core Identification: pink – grey – yellow – violet ⇂ Assembly: four cores twisted in two pairs (pink-grey – yellow-violet)Conductor AWG24: stranded tin copper wire 0,13mm; nominal 0,25mm² – AWG24; nominal diameter 0,65mm. Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 ⇂ Insulation: polyolefin; nominal diameter 1,20mm ⇂ Core Identification: white/green – brown/green (first colour is base, second colour is ring) ⇂ Assembly: two cores twisted in a pair Total Assembly: three pairs stranded together |

Conductor: Stranded Bare copper wire 0,15mm; nominal 0,75mm² – AWG19; nominal diameter 1,20mm. Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 ⇂ Insulation: polyolefin; nominal diameter 1,90mm ⇂ Core Identification: white/green – white/blue (first colour is base, second colour is ring) ⇂ Assembly: two cores twisted in a pair ⇂ Screen: braid screen; tin copper wire; nominal optical coverage 90% ⇂ Protective Tape: tape under and over screen |

|

| 4xAWG16 | Assembly | |

| Conductor: stranded bare copper wire 0,15mm; nominal 1,50mm² – AWG16; nominal diameter 1,50mm. Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 ⇂ Insulation: polyolefin; nominal diameter 2,50mm ⇂ Core Identification: black – brown – blue – green/yellow |

4xAWG16 + 1x(2xAWG19) + (2xAWG24+2x2xAWG28) stranded together around a central fibrous filler; some fibrous fillers could be used for a better roundness | |

| Screen | Protective Tape | |

| Braid type; tin copper wire; nominal optical coverage 85% | Tape under and over screen | |

| Sheath | Electrical | |

| Outer sheath: PUR, 90 ShA; diameter 13,60 ±0,30mm Colour: orange similar RAL 2003; conform to UL Style 21223 |

Operating voltage: 1000Vrms Test voltage (AWG 28/24): 1000 Vac Test voltage (AWG 19/16): 3000 Vac Conductor resistance (AWG28): 238,5 Ω/Km linear Conductor resistance (AWG24): 85,5 Ω/Km linear Conductor resistance (AWG19): 27,7 Ω/Km linear Conductor resistance (AWG16): 13,7 Ω/Km linear Insulation resistance: 500 MΩ x Km |

|

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -25 °C to +80 °C |

Bending radius, fixed: 5 x Ø Bending radius, flex: 8 x Ø (10 x Ø recommended) |

|

| Movement Data | Flame | |

| Bending cycles: 5 Mio (10 Mio bends) Speed: 300m/min Acceleration: 50m/sec² Torsion: optimal recommended ±30 °/m (length 1m) |

UL Cable Flame Test; CSA FT1; IEC 60332-1-2 | |

| Approval | ||

| Oil-resistant: UL 758 UV-resistant: yes Microbe-resistant: yes Halogen-free: CEI EN 60754-1 / VDE 0482-754-1 Hydrolysis-resistant: EN 50396 Hydraulic fluid, coolant emulsionant, alkali: resistant to a large extent |

B&RENDAT16PUR

| Code | B&RENDAT16PUR |

|---|---|

| Cable Type | 4 x 1,5 + 1 x (2 x 0,75) + (2 x 0,25 + 2 x 2 x 0,10) |

| Ø mm | 13,6 |

| Tolerance | ±0,30 mm |