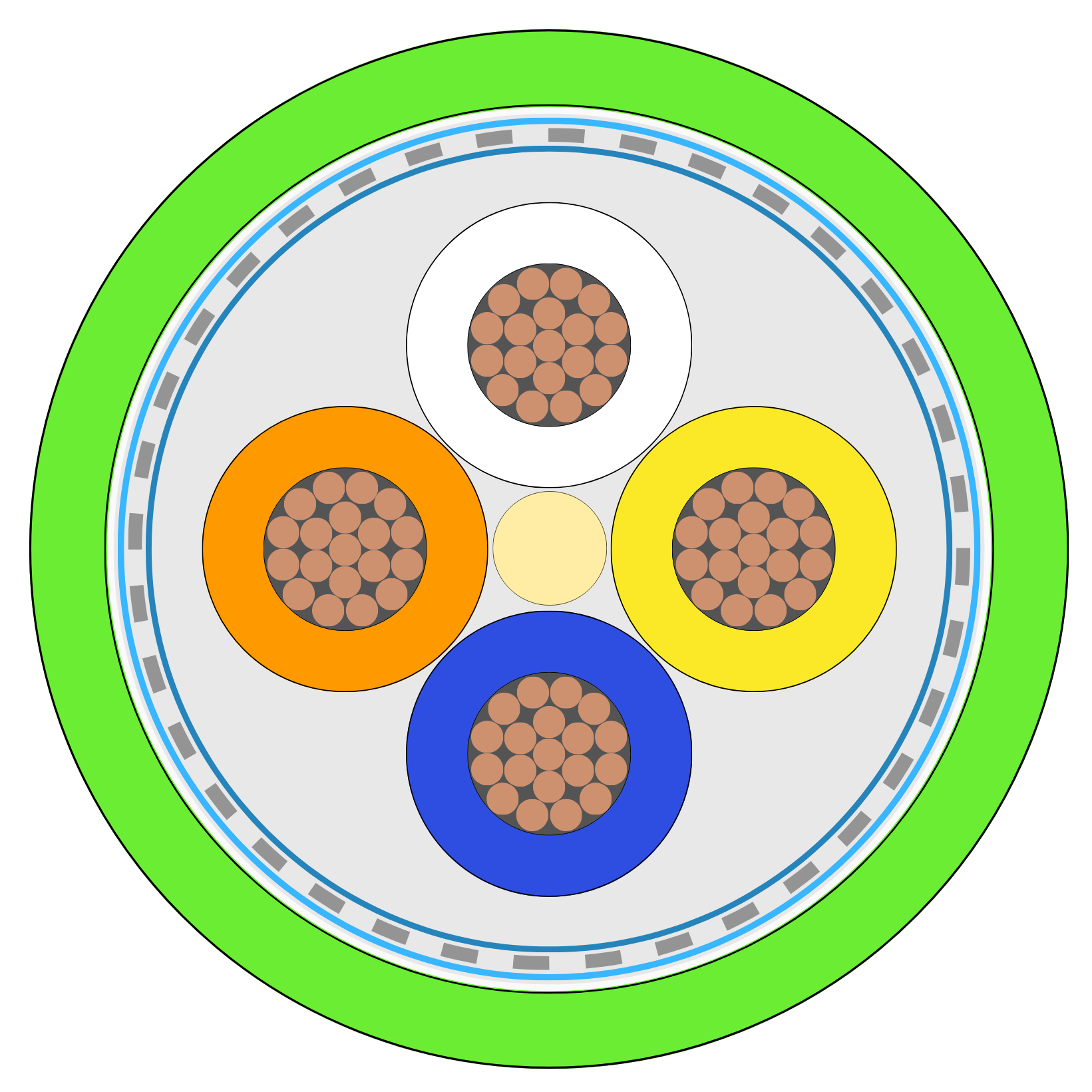

| Conductor | Insulation | |

| Tinned copper strand (Class 6 EN60228); according to EN 13602 – ETP1; stranding according to DIN VDE 0295 Stranded lay compliant with UL 758 |

Thermoplastic PE; insulation resistance @20°C >200 MΩxkm (IEC60189-1 & IEC60885-1 or EN50289-1-4); nominal hardness 61 Shore D; according to UL758 | |

| Core Identification | Assembly | |

| Color cores: yellow – blue – orange – white | Cores stranded together around a central filler | |

| Screen | Protective Tape | |

| First: Al/PET tape (aluminum face outside), nominal optical coverage 100% Second: braid type; tin copper wire, nominal optical coverage 80% |

Tape over braid screen | |

| Sheath | Electrical | |

| Inner sheath: flame retardant compound; nominal diameter 4,30mm; colors natural Outer sheath: special compound polyurethane based, nominal hardness 78 Shore A Colour: green similar RAL6018 |

Test voltage: 1500 V x 1 min. Operating voltage: 600 Vrms Nominal impedance: 100 Ω Nominal capacitance: 55 pF/m Nominal capacitance (Core/Screen): 105 pF/m Attenuation @100Mhz: < 32dB/100m |

|

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -10 °C to +70 °C |

Bending radius, fixed: 5 x Ø Bending radius, flex: 7,5 x Ø |

|

| Movement Data | Flame | |

| Speed: up to 300 m/min Acceleration: up to 60 m/sec² Torsion: ± 30°/m Max installation pulling force: 50 N |

UL Cable Flame Test; UL VW-1, CSA FT1; IEC 60332-1; IEC 60332-2 | |

| Approval | ||

| Oil-resistant: UL 758 UV-resistant: UL 1581 Silicone, Pb, Cd, Hg, FCKW free: Yes ⇂ Accordance to: – 2014/35/UE; 2014/30/UE; 2011/65/CE; 2015/863/UE – ProfiNET cabling and interconnection technology; Guideline for ProfiNET (3.1 March 2014) – Cat.5e flex patch cord – Weld Slag Resistance: yes, S-300 Molex test – UL/CSA – EtherCAT® – ECOLAB® |

BUSPROFINETWSOR

€0.00

| Code |

BUSPROFINETWSOR |

|---|---|

| Cable Type |

2 x 2 x 0,34 |

| Ø mm |

6,8 |

| Tolerance |

±0,20 mm |