| Conductor | Insulation | |

| Stranded bare copper wire; nom. 0,25mm² – AWG24; nominal diameter 0,60mm; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 | PE compound; nominal diameter 1,20mm | |

| Core Identificaton | Assembly | |

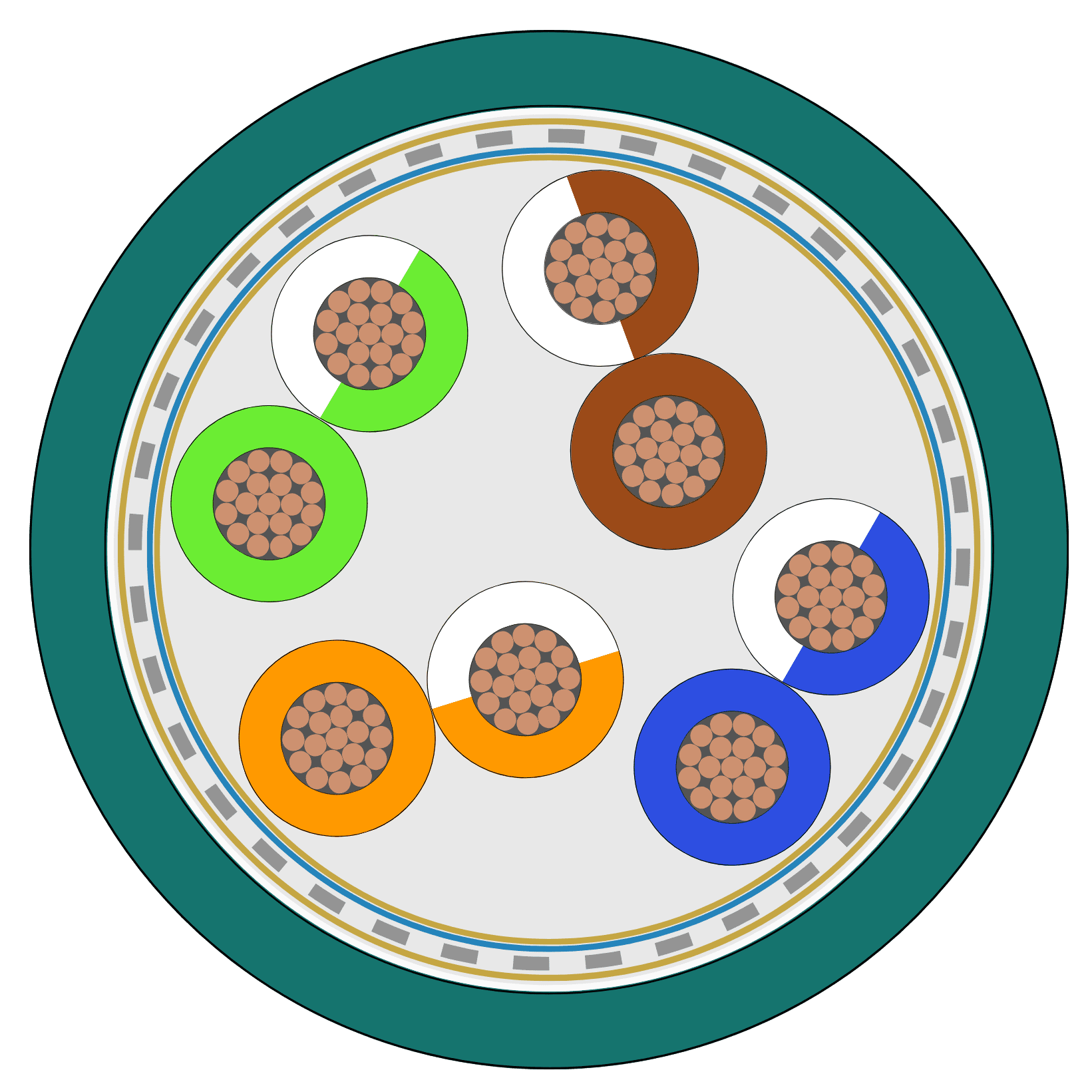

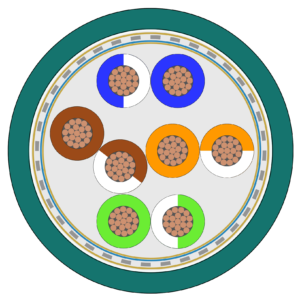

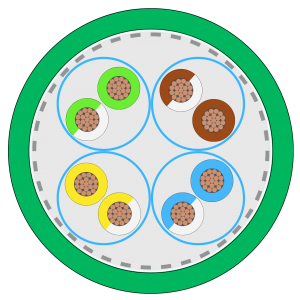

| Colour cores: orange/white polarized orange – green/white polarized green – brown/white polarized brown – blue/white polarized blue | Pairs: cores twisted in pairs (orange/white pol. orange – green/white pol. green – brown/white pol. brown – blue/white pol. blue) Total: pairs 4x(2xAWG24) stranded together; some filler could be used for a better roundness | |

| Screen | Protective Tape | |

| First: Al/PET tape; Al face outside; nominal optical coverage 100% Second: braid type; tin copper wire; nominal optical coverage 85% | Nonwovens tape (TNT) over total assembly and over total screen | |

| Sheath | Electrical | |

| Outer sheath: PUR compound (ether base); 92 ShA; diameter 7,80 ±0,20mm Colour: green similar RAL6026 | Operating voltage: 300 Vrms Test voltage: 1000 Vac Insulation resistance: ≥ 1 GΩxKm Conductor resistance: 97,5 Ω/Km (IEC 60344) Capacitance @1KHz: 55 nF/Km (nominal) Characteristic impedance: 100 Ω ± 15 Ω Propagation velocity: approx. 67% Propagation delay: max. 530 ns / 100m Delay skew: 40 ns / 100m Transfer impedance: < 30 mΩ/m @ 10MHz | |

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -25 °C to +80 °C | Bending radius, fixed: 5 x Ø Bending radius, flex: 7,5 x Ø (up to 3 Mio Bending cycles / 6 Mio Stroke) Bending radius, flex: 12,5 x Ø (up to 10 Mio Bending cycles / 20 Mio Stroke) Bending radius, flex: 15 x Ø (up to 12 Mio Bending cycles / 24 Mio Stroke) | |

| Movement Data | Flame | |

| Speed: up to 300 m/min Acceleration: up to 60 m/sec² Torsion: ± 30°/m (max. cycles 2Mio) | UL Cable Flame Test; CSA FT1; IEC 60332-1 | |

| Approval | ||

| Oil-resistant: UL 758 Halogen-free: CEI EN 60754-1 / VDE 0482-754-1 ⇂ Accordance to: – Cat.6 Flex Patch Cord – IEC 61156-6 – ISO 11801-2 – ANSI/TIA 568-C.2 |

BUSETHCAT6PUR

€0.00

| Code | BUSETHCAT6PUR |

|---|---|

| Cable Type | 4 x 2 x 0,25 |

| Ø mm | 7,8 |

| Tolerance | ±0,20 mm |