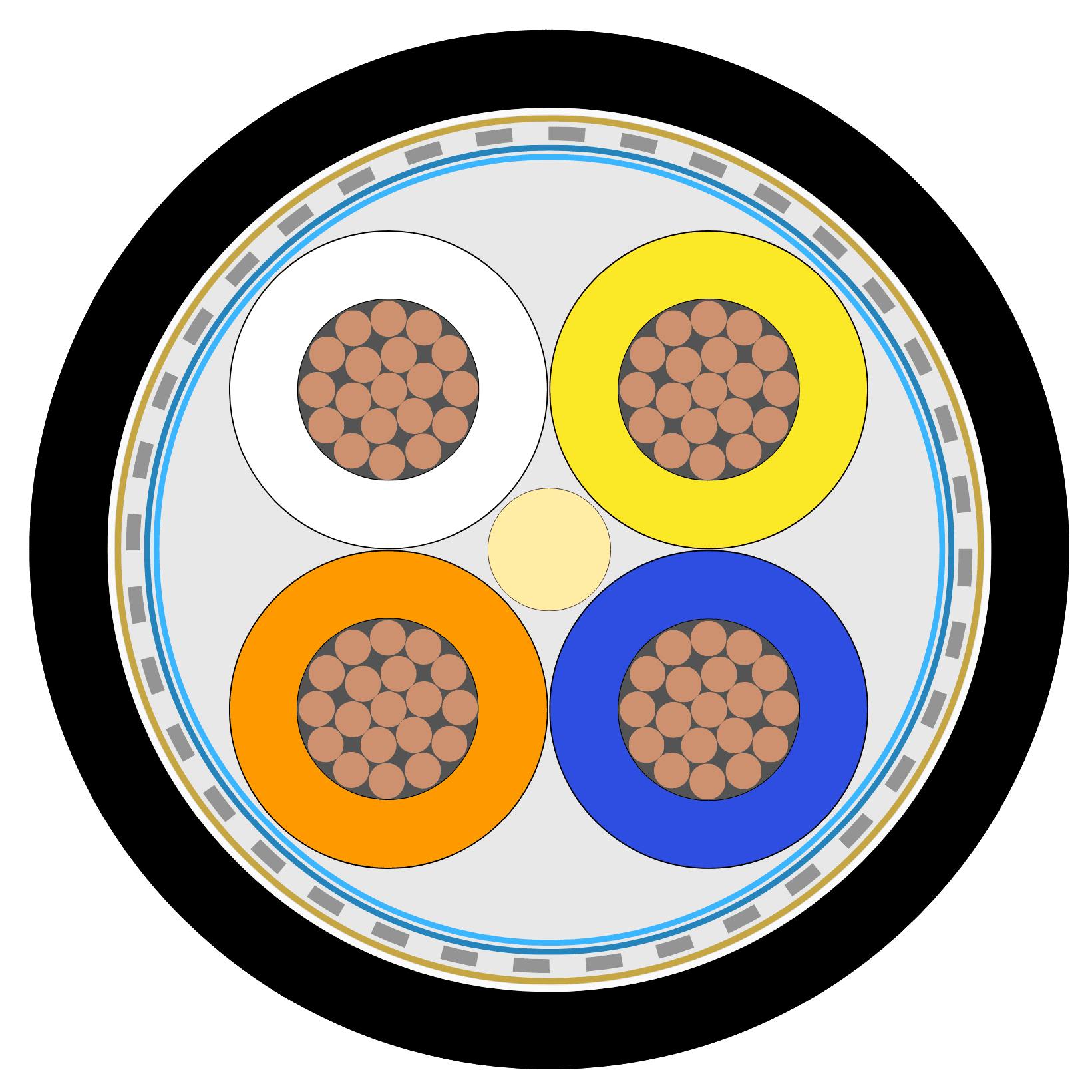

| Conductor | Insulation | |

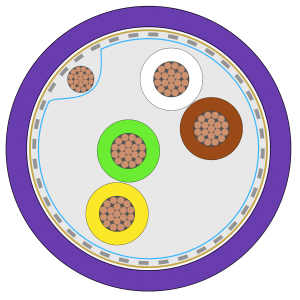

| Stranded bare copper wire; nom. 0,2mm² – AWG24; nominal diameter 0,6mm Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 |

Polyolefin compound; nominal diameter 1,45mm | |

| Core Identification | Assembly | |

| Colour cores: white – yellow – blue – orange | Four cores stranded together around a central solid filler Solid filler reinforced in para-aramid fibre (Kevlar); density 1,44 gr/cm3; elongation at break 3,4%; tenacity typical 200 N |

|

| Screen | Protective Tape | |

| First: Al/PET tape (Aluminium face outside), nominal optical coverage 100% Second: braid type; tin copper wire; nominal optical coverage 85% |

First: tape over assembly Second: tape over screen |

|

| Sheath | Electrical | |

| Outer sheath: PUR (ether base), 92 ShA; diameter 6,3 ±0,2mm; conform to UL AWM Style 20233 Colour: black similar RAL9005 |

Test voltage: 1500 Vac Operating voltage: 3000 Vrms Conductor resistance: 97,5 Ω/Km (IEC60344) Nominal characteristic impedance: 100 Ω Nominal capacitance @1KHz: 55 pF/m Nominal inductance: 0,5 µH/m |

|

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -25 °C to +80 °C |

Bending radius, fixed: 5 x Ø Bending radius, flex: 10 x Ø |

|

| Flame | Approval | |

| UL Cable flame test; CSA FT1; IEC 60332-1-2 | Oil-resistant: UL758 Halogen-free: CEI EN 60754-1 / VDE 0482-754-1 Silicone, Pb, Cd, Hg, FCKW free: yes |

BUSCAN4X0,25PURKEV

€0.00

| Code | BUSCAN4X0,25PURKEV |

|---|---|

| Cable Type | 4 x 0,25 |

| Ø mm | 6,3 |

| Tolerance | ±0,20 mm |