| Conductor | Insulation | |

| Stranded bare copper wire 0,10mm (Class 6); nom. 0,34mm² – AWG22; nominal diameter 0,80mm; VDE 0295 Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 | Polyolefin; nominal diameter 1,27mm | |

| Core Identification | Assembly | |

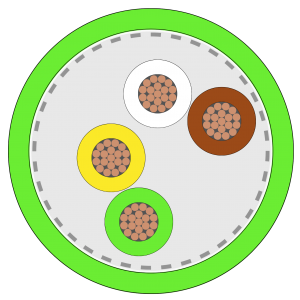

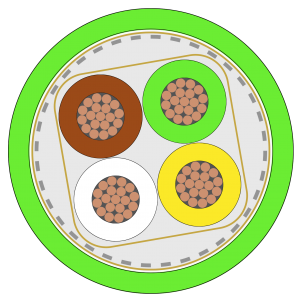

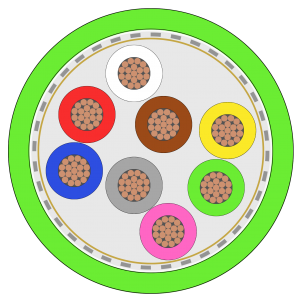

| Colours acc. to DIN 47100 | Pair: cores twisted in pairs (white-brown – green-yellow – grey-pink) Total: three pairs stranded together; some fillers could be used for a better roundness | |

| Screen | Protective Tape | |

| Braid type; tin copper wire; nominal optical coverage 85% | Tape under and over screen | |

| Sheath | Electrical | |

| Outer sheath: PUR (ether base); hardness 92 ShA; diameter 7,50 ±0,25mm Colour: green similar RAL 6018; conform to UL AWM Style 20233 | Operating voltage: 300 Vrms Test voltage: 2000 Vac Conductor resistance: 65,3 Ω/Km (IEC 60344) | |

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -20 °C to +80 °C | Bending radius, fixed: 5 x Ø Bending radius, flex: 10 x Ø | |

| Flame | Movement Data | |

| UL Cable flame test; CSA FT1; IEC 60332-1-2 | Speed: 300 m/min Acceleration: 10 m/sec² Bending cycles: up to 5 Mio (10 Mio Stroke) | |

| Approval | ||

| Oil-resistant: UL 758 UV-resistant: yes Halogen-free: CEI EN 60754-1 / VDE 0482-754-1 Silicone, Pb, Cd, Hg, FCKW free: yes |

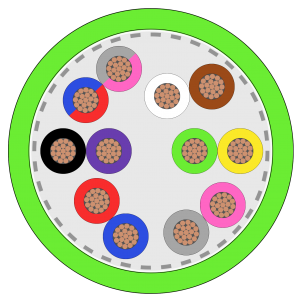

SS3X2X0,34

| Code | SS3X2X0,34 |

|---|---|

| Cable Type | 3 x 2 x 0,34 |

| Ø mm | 7,5 |

| Tolerance | ±0,25 mm |

| Weight Kg/Km | 75,0 |