| Conductor | Insulation | |

| Stranded tinned copper wire (Class 6 VDE0295); nom. 0,35mm² – AWG22; nominal diameter 0,8mm Lay agree with UL 758 tab 5,9; conform to EN 13602 – ETP1, DIN 40500 E-Cu 58 | Foam PE (with internal and external skin); nominal diameter 1,5mm | |

| Core Identification | Assembly | |

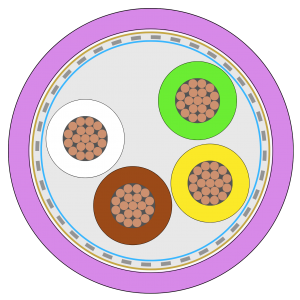

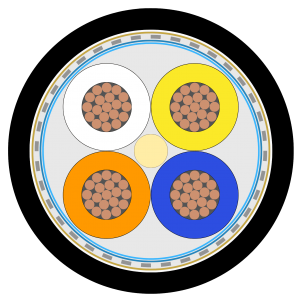

| Colour cores: white – brown – green – yellow | Pairs: four cores twisted in two pairs (white-brown – green-yellow) Total: two pairs stranded together; some filler will be used for a better roundness | |

| Screen | Protective Tape | |

| Braid type; tinned copper wire; nominal optical coverage 85% DW: stranded tinned copper wire; nom. 0,35mm² – AWG22; nominal diameter 0,8mm; under braid screen | First: tape over total assembly Second: tape over screen | |

| Sheath | Electrical | |

| Outer sheath: special compound polyurethan based; 76 ShA; diameter 7,4 ±0,2mm; conform to UL AWM Style 21215 Colour: violet similar RAL4001 | Test voltage: 700 Vac Operating voltage: 600 Vrms (for electronic use) Conductor resistance: 63,8 Ω/Km (IEC60344) Nominal impedance: 120 Ω Nominal capacitance: 40 pF/m | |

| Temperature | Bending Radius | |

| Operating temperature range, fixed: -40 °C to +80 °C Operating temperature range, flex: -25 °C to +80 °C | Bending radius, fixed: 5 x Ø Bending radius, flex: 10 x Ø | |

| Movement Data | Flame | |

| Speed: 180 m/min Acceleration: 10 m/sec² | UL Cable flame test; CSA FT1; IEC 60332-1-2 | |

| Approval | ||

| Oil-resistant: UL758 Silicone, Pb, Cd, Hg, FCKW free: yes |

BUSCAN2X2X0,34WSOR

€0.00

| Code | BUSCAN2X2X0,34WSOR |

|---|---|

| Cable Type | 2 x 2 x 0,34 |

| Ø mm | 7,4 |

| Tolerance | ±0,20 mm |